After listening 2 workshops in Engrave-In 2009 about die making, I just had to try it out myself. Dies are used in making certain items in large quantities. Coins, pins and all that kind of things are struck with dies. In current digital age most of the dies are made with CNC machines, but I like handmade things. So I’m making one by hand.

The steel I use is Uddeholm K600, which is special die steel that is tough and is designed especially to handle striking.

The overall process is something like this:

- Create master die (that’s the one I make now) – positive

- Heat treat master die

- Create the hub (negative, or working die) by hubbing – press the positive heat treated die into another soft steel piece

- Heat treat the hub

- Start striking

So far I can do steps 1 and 2, but the rest is currently unknown. I have to find some kind of relatively strong press for hubbing. Some say it should be at least in the range of 200-250 tons.

Even if I don’t find a press and can’t use this die for making any ‘coins’, it is still useful practice for sculpting. So I don’t worry about it too much right now.

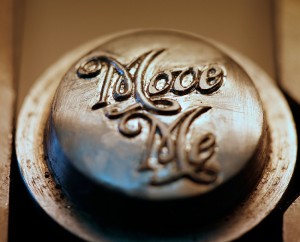

Here it is.

As you can see it is very simple design and that’s in purpose. I want to complete it and get at least somewhat decent result.

Way to go Viljo. You are doing awesome work.

Thank you, sensei 🙂

Wooow! Did you carve this out by removing all the material around it ???

Yes, you’ve got it exactly right.